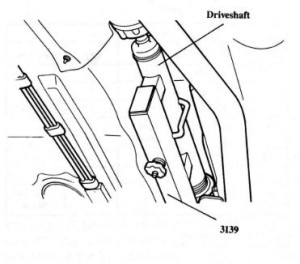

Install and tighten tool 3139 before removing driveshaft to prevent damage to the CV joints.

Install and tighten tool 3139 before removing driveshaft to prevent damage to the CV joints.

Spare parts are not available for the driveshaft. If shaft or joints are damaged, complete driveshaft must be replaced.

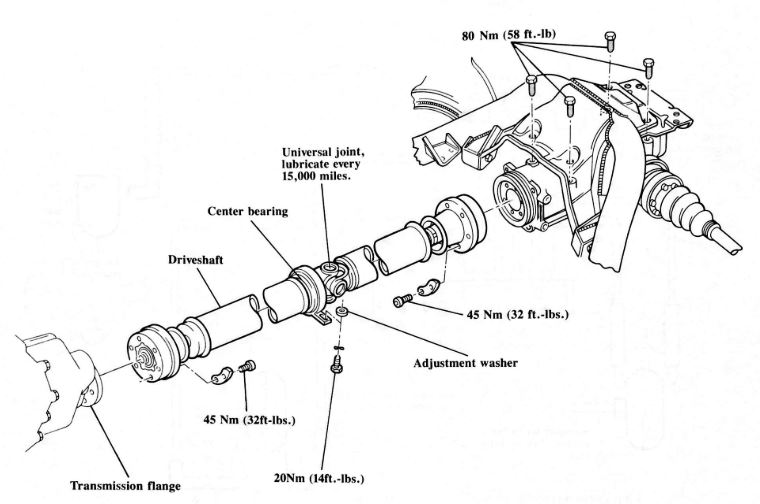

Whenever the driveshaft is removed, it will have to be readjusted. To adjust the driveshaft:

- Clamp tool 3139 to driveshaft and tighten bolts

- Measure clearance “a” and install appropriate shim from the chart.

- Install shims and torque center bearing bolts to 20 Nm (14 ft-lbs).

[ezcol_1third]Dim A mm

0-3

3.1-5

5.1-7

7.1-9

9.1-11

11.1-13

[/ezcol_1third] [ezcol_1third]Thickness mm

–

2

4

6

8

10

[/ezcol_1third] [ezcol_1third_end]Part No

–

857 521 143

857 521 143A

857 521 143B

857 521 143C

857 521 143D

[/ezcol_1third_end]

The shim will preload the driveshaft to compensate for settling of the body.

The shim will preload the driveshaft to compensate for settling of the body.

With tool 3139 in position, the lateral (side to side) adjustment of the driveshaft is made automatically.

If internal transmission or rear differential repairs are necessary, the complete transmission or rear differential must be exchanged.

If internal transmission or rear differential repairs are necessary, the complete transmission or rear differential must be exchanged.

However, replacement of some external oil seals is possible. Two new tools have been introduced for seal replacement.

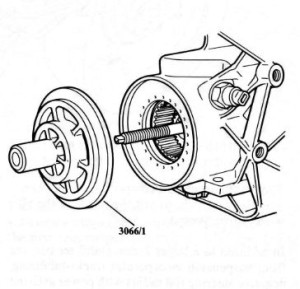

To replace the rear differential drive flange oil seal:

• Remove old seal

• Install threaded sleeve, tool 3066

• Tool 3066/1 is used to pull the new seal into position

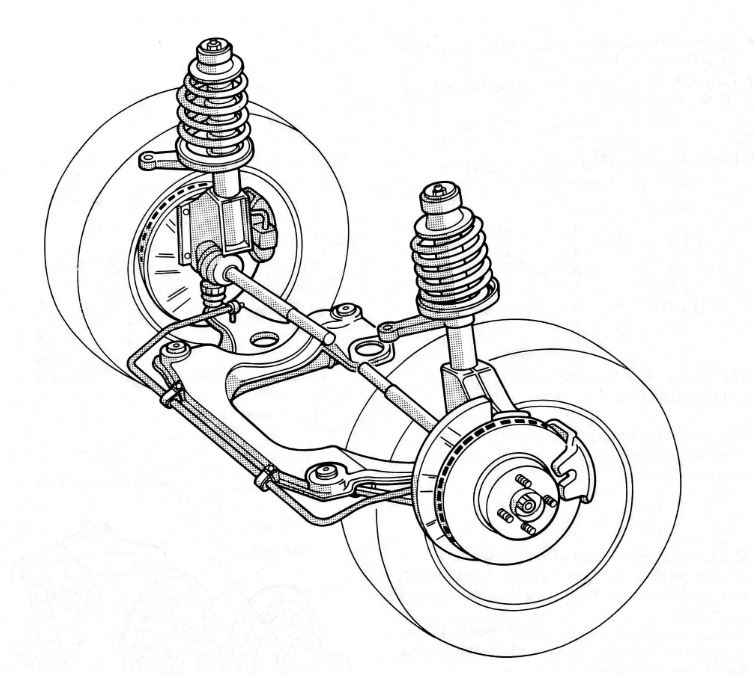

The front suspension components have been modified specially to suit the needs of the all wheel drive Syncro.

The front suspension components have been modified specially to suit the needs of the all wheel drive Syncro.

In addition to a larger 26mm stabilizer bar, the front suspension incorporates track-stabilizing negative steering roll radius with power assisted rack and pinion steering to maintain directional stability under all driving conditions.

Additionally, the Mark II disc brake calipers, brake discs, wheel hubs and splash shields have all been modified for the Syncro, as have the shock and spring rates.