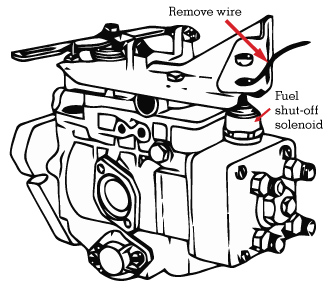

- Remove wire from fuel shut-off solenoid and insulate the wire.

- Clean connections on injector lines.

- Remove injector lines (be sure that delivery valves are not loosened when loosening injector lines on injection pump.).

- Remove injectors using deep well socket and store in clean area.

- Remove all heat shields except #1 cylinder. Caution: loose heat shields can be blown out during compression check.

- Install adapter on #1 cylinder.

- Install diesel compression test gauge onto adapter.

- Operate starter until gauge reads highest reading.

- 28-34 bar (400 – 500 psi)

- maximum cylinder variation 5 bar (71 psi)

- Release pressure

- Repeat process on remaining cylinders.

- Low readings on adjacent cylinders gasket = leakage between cylinders.

- Low readings on one cylinder = valve leakage.

- Low readings on all cylinders = worn pistion rings or jumped valve timing

- A low reading can be rechecked by adding 1 tablespoon of engine oil through the injector hole:

- If the compression readings increase slightly this indicates valve leakage.

- If the compression readings increase significantly this indicates worn piston rings.

- If compression does not increase, check valve timing.

Always install new heat shields before reinstalling injectors.