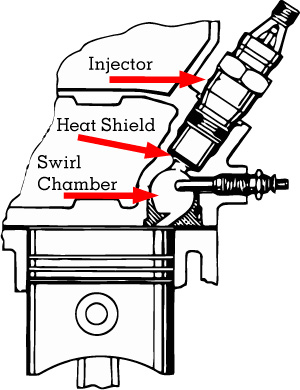

A swirl chamber is located in the cylinder head. Diesel injectors spray fuel directly into the swirl chamber near the end of the compression stroke. It is in the swirl chamber that air and fuel begin to burn.

A small passage leading from the swirl chamber connects it to the cylinder. The burning air and fuel expand down through this passage and the rest of combustion occurs in the narrow scalloped section of

the piston.

The injectors are protected from the heat of combustion by a heat shield. The heat shield acts as an insulating and sealing washer.

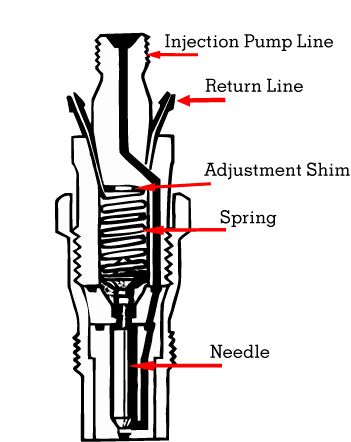

Fuel pressure from the injection pump forces the needle up against spring pressure so that the injector sprays a cone shaped mist of diesel fuel at the precise time for ignition.

A small amount of fuel bleeds around the injector needle to lubricate and cool the injector – this fuel returns to the tank via a separate fuel line.

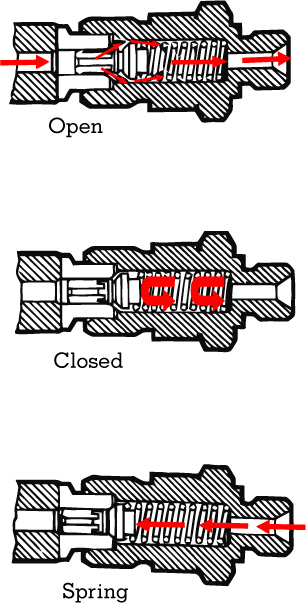

[ezcol_1half]At the start of injection the delivery valve opens and pressurized fuel flows to the injector.

At the end of injection the delivery valve closes. Fuel is now trapped in the injection line.

In addition, the force of the spring pushes the valve further into its seat and the trapped fuel now expands. The sudden drop in pressure, caused by the expanding fuel, allows the injector to snap shut. This eliminates fuel “dribble”.[/ezcol_1half] [ezcol_1half_end]