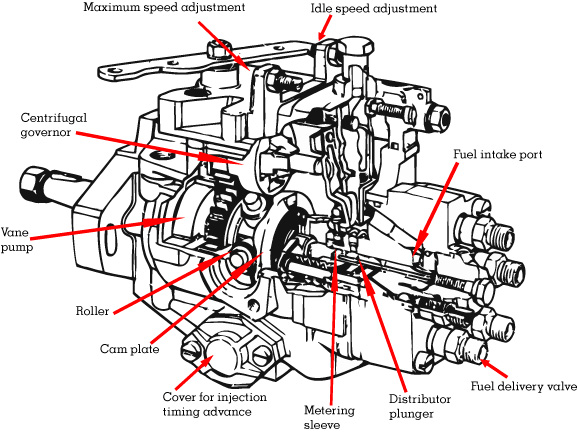

The injection pump used on the four cylinder diesel is a single-plunger mechanical pump and performs the following functions:

- It pressurizes the fuel

- It meters the fuel according to engine load and speed

- It times the fuel delivery at the precise time

- It distributes fuel to the injectors in the correct firing sequence

The injection pump is driven by the camshaft spur belt at one-half crankshaft speed. The injection pump is maintenance free and is lubricated by the diesel fuel passing through it; clean fuel is essential to pump reliability.

The following repairs and adjustments to the injection pump are possible:

• Replacing fuel shut-off solenoid

• Replacing fuel delivery valve bodies

• Replacing fuel delivery valve gaskets

• Adjusting idle and maximum speed

• Adjusting injection pump timing

All other causes of injection pump malfunction necessitates pump replacement.

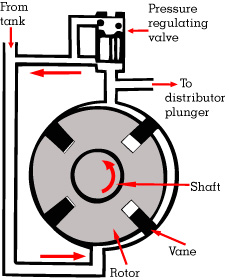

Vane Pump

The rotary vane pump located inside the injection pump draws fuel through the fuel filter from the fuel tank.

The vane pump rotor is driven off of the injection pump driveshaft which in turn is driven by the engine-camshaft spur belt.

Centrifugal force holds the vanes against the walls of the pressure chamber as the rotor spins. This squeezes the fuel trapped between the vanes and forces it toward the distributor plunger.

The vane pump supplies a constant quantity per revolution and fuel pressure in the pressure chamber is regulated by the pressure regulating valve at between 3-7 bar depending upon engine speed.

The vane pump does the following:

- Transfers fuel from the fuel tank to the injection pump

- Pressurizes the fuel

- Lubricates moving parts in the injection pump

- Supplies fuel to the distributor plunger for the injectors

- Operates the injection timing advance mechanism

The vane pump and vane pump pressures cannot be serviced or checked in the workshop.