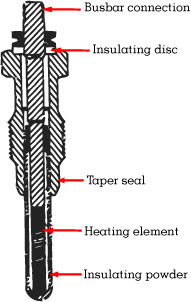

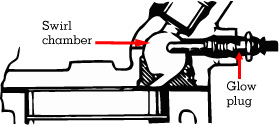

Glow plugs are installed in the diesel engine as a preheating provision to aid in cold starting. Two types of glow plug systems are used: 1) quick glow system and 2) normal glow system.

The time actually required for preheating depends on cylinder head temperature.

Voltage is supplied to the glow plugs from the battery via the glow plug relay.

With the ignition switch “on” voltage flows to energize the glow plug relay.

The temperature sensor, connected to a time circuit in the relay, determines whether or not the relay gets activated. It also determines pre-heat time.

The colder the engine the longer the pre-heat time.

The glow plug relay performs the following

functions:

- Pre-glow — pre-heating time with the with the igntion key on (t15) — (time depends upon temperature sensor)

- After-glow — pre-heating time with the ignition key on (t15) after the glow plug light goes out (after glow lasts a few seconds).

- Cranking glow — pre-heating time with the ignition key in the cranking mode (t50).

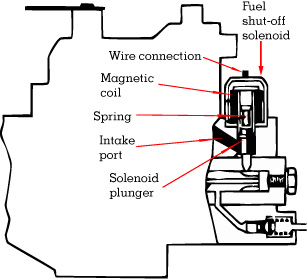

Diesel engines are switched off by a fuel shut-off solenoid on the injection pump.

Current is supplied to the fuel shut-off solenoid whenever the ignition switch is “on.” The magnetic coil pulls the solenoid plunger up against the spring, opening the filling port.

When the ignition switch is turned off, the solenoid plunger closes the filling port, cutting off the supply of fuel for injection from the vane pump.

The engine will not run if the fuel shut-off solenoid sticks closed or does not receive current; if it sticks open, the engine will continue to run after the ignition is turned off.

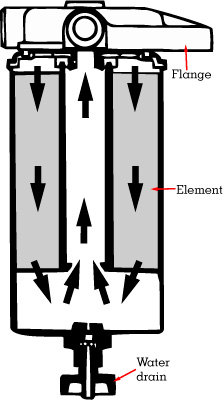

Diesel fuel systems operate reliably as long as the fuel is free from dirt and water. Moving parts inside the injection pump and injectors can be damaged by a small amount of dirt or corrosion.

The diesel fuel filter is designed to stop any dirt or water before it reaches the pump. The replaceable element is similar to an oil filter — it threads onto a removable flange in the engine compartment.

The filter element should be replaced or drained at normal maintenance intervals to ensure reliable operation of the pump and injectors. To prevent freezing and blocking of the filter in cold weather, a water drain is located in the bottom of the element.

The filtering mesh of the original equipment designed to allow sufficient fuel flow while maintaining maximum filtering capacity. It is important that only approved filters are installed during maintenance services or repairs.