Check battery charge

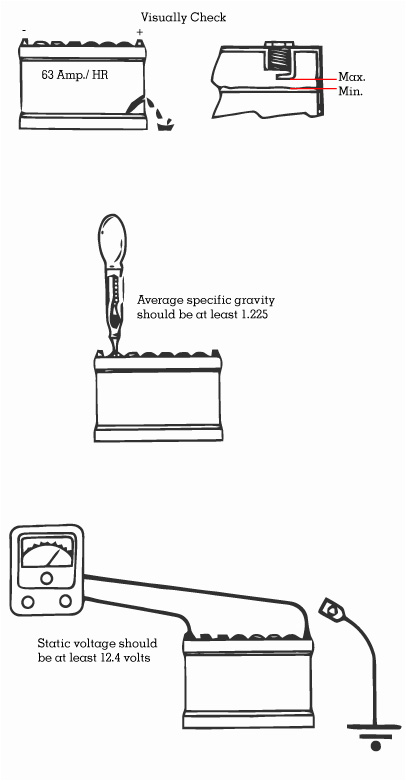

Visually check the battery to make sure:

Visually check the battery to make sure:

- The battery is clean

- The terminals are tight

- Each cell is filled with electrolyte

If water is added, the battery must be fast charged for several minutes to mix the water with the electrolyte, otherwise the hydrometer readings will be incorrect.

Non-maintenance free batteries

Measure the specific gravity in each cell, correcting for temperature if necessary.

- For every 10° F above 80° F, add .004

- For every 10° F below 80° F, subtract .004

- If specif ic gravity varies more than .050 between cells, replace the battery

If the specific gravity is above 1.225 the battery can be load tested.

Maintenance free batteries

Measure the static voltage of the battery.

- Turn the headlights on for 1 minute to remove any surface charge from the battery.

- Disconnect the battery ground strap and measure the static voltage.

If the static voltage is at least 12.4 volts the battery can be load tested.

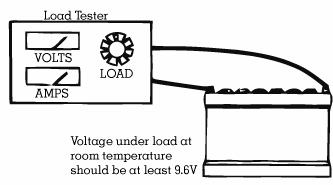

Load test battery

The battery must be at least 75% charged before performing a load test. If the average specific gravity is below 1.225 or the static voltage is below 12.4 volts, recharge the battery at 15 amps maximum for either 4 hours or until;

The battery must be at least 75% charged before performing a load test. If the average specific gravity is below 1.225 or the static voltage is below 12.4 volts, recharge the battery at 15 amps maximum for either 4 hours or until;

- The average specific gravity is above 1.225 or

- The static voltage is above 12.4 volts

Hook up load tester according to manufacturer’s instructions.

Adjust the load to either 3x the amp/hour rating or Vz the 0°F cold cranking capacity.

After 15 seconds:

- If the battery voltage is at least 9.6 volts the battery is o.k.

- If the battery voltage is below 9.6 volts replace the battery.

Check for correct battery installation

If a battery has been or needs to be replaced, the correct size battery must be used. There are two standards for identifying battery size and performance capability.

- Original equipment batteries are classified in the DIN (German) standard

- Replacement batteries are classified in the SAE (American) standard.

The two different standards result in two values for cold cranking capacity

[ezcol_1third]engine size

1.5 Liter

1.6 LIter[/ezcol_1third] [ezcol_1third]DIN

300 amps

380 amps[/ezcol_1third] [ezcol_1third_end]SAE

500 amps

620 amps[/ezcol_1third_end]

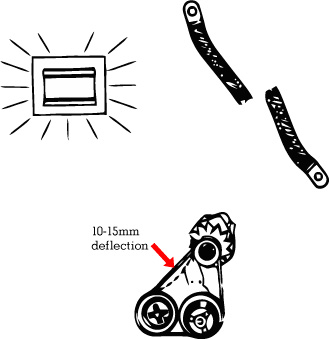

Check alternator

Visually check the alternator to make sure that:

Visually check the alternator to make sure that:

- The drive belt is not damaged and is adjusted properly.

- The ground strap (if applicable) is secure.

- The charging indicator light works when the ignition is turned on.

It is normal for the charging indicator light to stay on after the engine is started. However the light should go out and not come back on once the engine speed is increased. It is also normal for the light to glow dimly at low engine speeds when there is no load on the electrical system and the battery is fully charged.

Both of these characteristics are a result of the circuitry in the voltage regulator and do not represent a fault in the system.

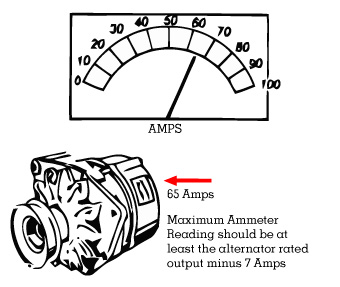

Test alternator output

Connect the alternator output tester according to the manufacturer’s instructions.

Connect the alternator output tester according to the manufacturer’s instructions.

Start the engine and run it at approximately 3000 rpm (make sure that all electrical consumers are switched off).

Slowly turn the load adjuster knob until the maximum ammeter reading is obtained. (Do not allow the system voltage to drop below 12 volts.)

The maximum ammeter reading should be the rated alternator output minus 7 amps (Diesel only).

If the ammeter reading is too low, replace the voltage regulator and retest. If the output is still too low, replace the alternator.

Test voltage regulator

Connect a voltmeter to the battery.

Turn off all electrical consumers.

Start the engine and run it at approximately 3000 rpm for 2 minutes to stabilize the system.

The voltmeter should read between 13.5 and 14.5 volts. The reading must be steady.

If voltage is out of specification, replace the regulator and retest.