INLET SILENCER

Make sure that the inlet holes on the filter are towards the front of the kart and that they are not plugged.

Make sure that the clamp on the carburetor is not loosen and that the filter is well fastened to the chassis.

Once a while, clean the inside from oil deposits. If necessary remove the rubber filter union and clean it with gasoline or solvent.

EXHAUST SYSTEM

Before every test, make sure that the flexible is not damaged. Replace if necessary.

ATTENTION: In case the flexible is damaged, metallic particles could be sucked in the engine and cause a seizure.

Always make sure that the springs are well hooked and in place. In case of breakage, replace the broken spring. Never race the kart without the 3 springs in place, as otherwise the exhaust pipe could vibrate beyond control.

Every 10 -15 hours, open the pipe end and make sure that the holes on the internal counter cone are not plugged.

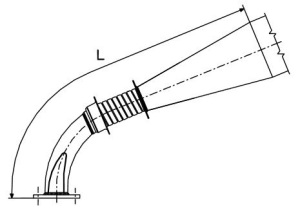

The best performance is achieved with a total exhaust length of:

Where L is measured from the flange on the exhaust header up to the first welding on the first cone of the exhaust muffler (see drawing).

To achieve this dimension, the flexible (supplied with the engine) must be cut at a length of 65mm (flexible completely closed). Having fixed a sprocket ratio, it could be necessary to improve the engine performance either at low or at high RPM.

This could be achieved by modifying the exhaust length.

In general, by shortening the total exhaust length an improvement at high RPM is achieved and vice versa, by lengthening the exhaust length the low RPM is improved. When testing, never exceed in lengthening or shortening the flexible by more than 5mm per time.

BATTERY

The battery (12 V – 7.2 Ah) included in the supply is sealed and without maintenance.

In order to lengthen the battery life it is necessary though to follow a few recommendations:

- When the tension drops below 12.6V it is necessary to recharge the battery.

- Max. allowed recharging current is 1.8A.

- The ideal recharge is achieved with an average charging current of 0.8 – 1 A (recharging time of appr. 10 h.) and at an ambient temperature between 0° and 40°C.

ATTENTION: An overcharge or an extremely quick charge with excessive current could damage the battery (the battery would tend to swell).

Choose a battery charger with the following characteristics:

- Feed Tension: 90/250 VAC – 50/60 Hz

- Outlet Tension: 15 V full charge – 13.8 standby

- Max outlet current: 2A full charge

ATTENTION: Always connect the – (negative) terminal before and the + (positive) terminal after. Always disconnect the battery in opposite order.

- During transportation or storage, the battery could loose its charge due to self discharge (0.1% max per day).

- Fully recharge battery before use.

- Recharge the battery at least once every 6 months.

- Never put the battery in contact with solvents, gasolines, oils, plastifiers or rags containing such elements. The external case of the battery could be damaged.

- Never press or bend or overheat (by welding) the battery terminals.

OTHER RECOMMENDATIONS:

- Pay attention not to have free fires upon or around the battery.

- Never shortcircuit the terminals.

- Never open the battery or throw it in the fire.

- In case the electrolite (diluted Sulfuric acid) gets in contact with skin or clothes,

- immediately wash with water. In case it gets in touch with eyes, wash and apply for medical assistance.

- Carefully check the external case of battery and replace in case of breakages, swellings of the case or of battery cover.

- Before use, clean the battery from dust and check that the terminals are not oxidyzed or damaged.

- When the battery comes to an end never throw it in the garbage, but deliver it to an authorized disposer.

SPARKPLUG AND THERMAL DEGREE

The engine is supplied with a standard NGK BR10EG sparkplug which represents a good compromise between the needs of a good break-in and the racing needs in normal conditions.

Use of different sparkplugs is possible and, as a general information, we are attaching a correspondence list among sparkplugs of other brands based on thermal degree which represents the capacity of the sparkplug to dissipate the internal heat. The colour of the various parts of the sparkplug more exposed to the combustion

flames gives a good indication on the adequacy of the thermal degree and on the carburetion. It is necessary though to understand which of the two parameters has to be changed and only the experience tells how to identify the most proper thermal degree of a sparkplug as lean or rich mixtures can generate the same final look

which can also be achieved with a hot or cold sparkplug.

See table:

[ezcol_1third]-

BOSCH

W08CS

W07CS

W06CS

[/ezcol_1third] [ezcol_1third]HOT

NGK

BR9EG

BR10EG

BR11EG

COLD[/ezcol_1third] [ezcol_1third_end]-

CHAMPION

N54R

N52R

[/ezcol_1third_end]

- An excessively warm sparkplug shows the symptoms listed:

- Extremely clear color, porous lock and calcification of

the electrodes and of the internal insulation. - Irregularities in the ignition, preignition and detonation with tendency to perforate the top of the piston.

- Some of these symptoms can be achieved with lean mixtures.

- Use a warmer than standard plug with cold or rainy climates

- Extremely clear color, porous lock and calcification of

- A correct thermal degree shows:

- Colour of the insulator end from yellow grey to dark brown for mixtures respectively lean or rich.

- An excessively cold sparkplug shows the symptoms listed:

- Insulator end and electrodes covered with black

shady soot. - Ignition difficulties.

- A wet or oily electrode could also mean an excessively rich mixture

- Use a colder than standard sparkplug with hot climates.

- Insulator end and electrodes covered with black