Check for excess intake air entering the engine

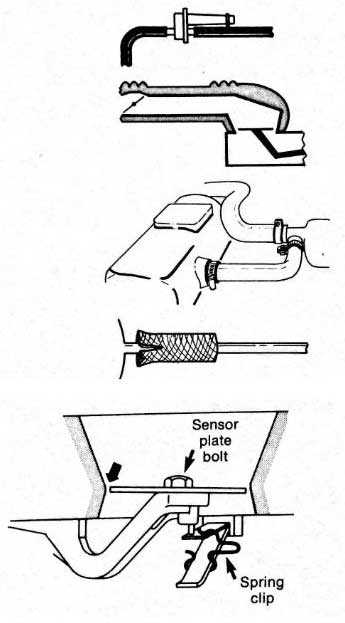

- Check Hoses and Boots Check carefully for leaks:

- Hoses and clamps for auxiliary air regulator.

- Boots, ducts and clamps connecting air flow sensor to throttle valve.

- PCV hoses, clamps.

- Vacuum hoses, clamps, reservoirs.

- Check the Air Sensor

- The air sensor plate is lifted from the air cone during starting and running.

- The air sensor plate height should be checked with the engine off, warm, and with residual fuel pressure still in the system (within 10 minutes after shut off)

- The sensor plate should be even with the bottom rim of the air cone at the edge nearest the fuel distributor.

- To adjust bend spring clip up or down.

- The sensor plate should also be centered in the air cone.

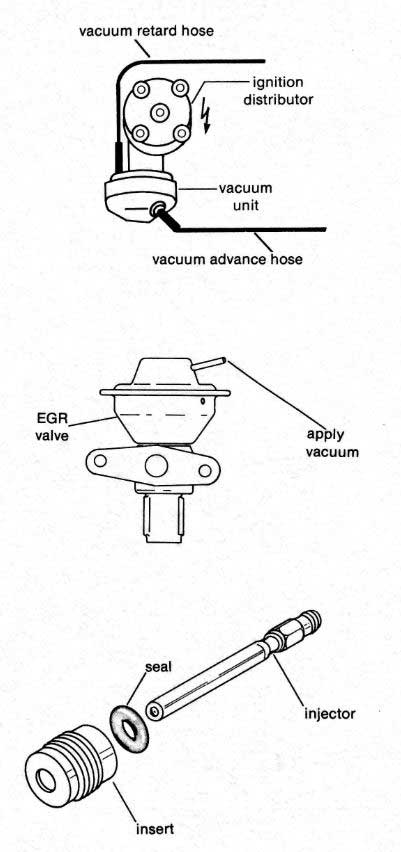

- Check Vacuum Advance and Retard

- With the engine idling remove the vacuum retard hose – idle speed should increase if the vacuum retard is working.

- Reconnect the vacuum retard hose.

- Increase engine speed to 3000 RPM, remove vacuum advance hose – engine speed should decrease if vacuum advance is working.

- Reconnect vacuum advance hose.

- With the engine idling remove the vacuum retard hose – idle speed should increase if the vacuum retard is working.

- Check EGR Valve

- The EGR valve must be closed during starting and idling.

- With engine idling, connect a vacuum pump and apply vacuum:

- Valve should open

- Engine speed should decrease

- Release vacuum:

- Valve should close

- Engine speed should increase to normal

- Check Injector Seals And Inserts

- Remove injectors and check injector seals and inserts.

- Check injector seals carefully for damage or looseness.

- Check that the injector inserts are tight with 12mm hex wrench.

- If inserts are loose:

- Remove inserts

- Clean threads

- Apply Loctite T with Loctite 620 (or equivalent).

- Torque inserts to 22Nm (16 ft.lbs.)

- Check injectors before installing (see following page)